Ductile iron have the following characteristics: high strength, plasticity, toughness, wear resistance, thermal and mechanical shock, severe high temperature or low temperature, corrosion resistance and dimensional stability, use is very extensive.

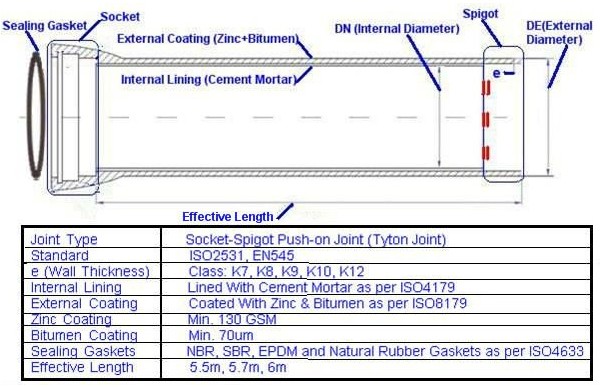

Specifications of Ductile iron pipe

ISO2531 Ductile Iron Pipe K9 Class

Cement Mortar Lining as per ISO4179

Zinc(130GSM) & Bituminous Coating(70UM) as per ISO8179

Tyton on joint

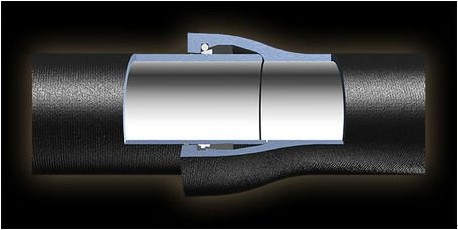

"Tyton" is the name of a push-on joint. This designs incorporate a single rubber sealing gasket assuring a tight, permanent seal. The push-on type joint is easy to assemble and fast to install. The push-on design eliminates the need for glands and fasteners. The rubber gasket fits inside the contour of the bell socket, which seats the gasket. The spigot end of each pipe is beveled to further ease assembly.

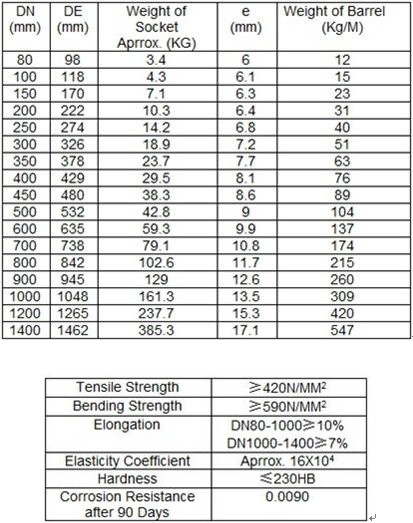

Sizes:

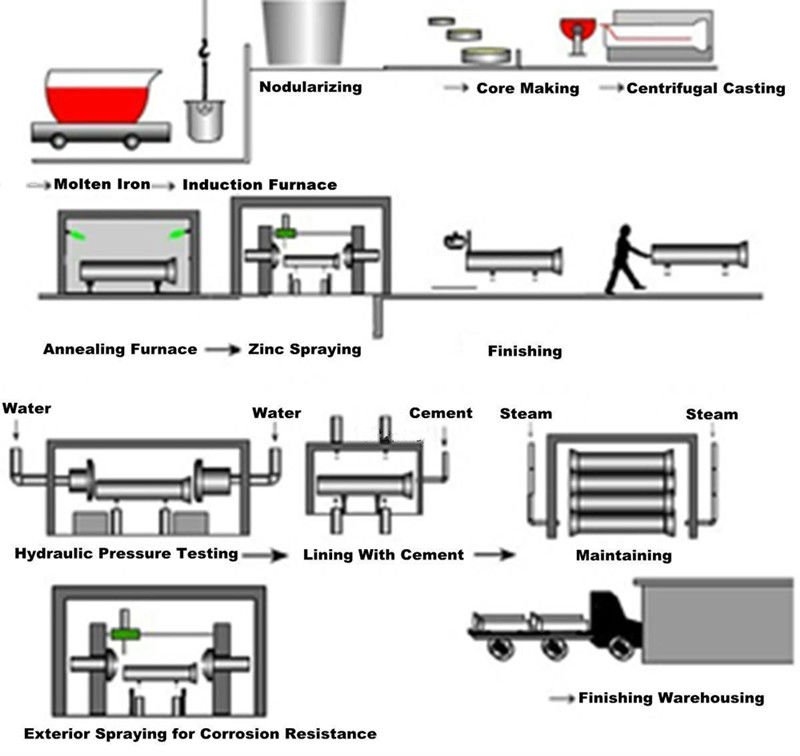

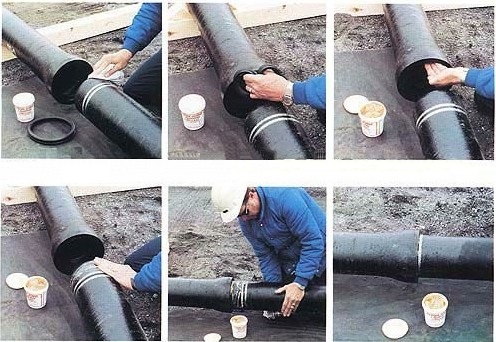

Step 1. Thoroughly clean out the bell with special attention to the gasket recess. Remove any foreign material or excess paint. Clean the spigot or beveled plain end and remove any sharp edges with a standard file.

Step 2. After making sure that the correct gasket is being used, insert it into the recess in the bell with the small end of the gasket facing the bell face.

Step

Step 4. Guide the plain end into the bell and, while maintaining straight alignment, push the plain end into the bell socket. Once the joint is assembled, necessary deflection can be accomplished. When assembly is complete, the bell face should be aligned between the two white depth rings.

English

English Japanese

Japanese

.jpg)